Spotlight feature: scuffing assessment in SABR-Gear

The 2021.1 release from Ricardo Software is now available to download. Customers can benefit from a wide range of new features and enhancements that will further help to improve accuracy, whilst reducing time spent on development.

We caught up with our Product Managers to deep-dive into some of the biggest enhancements and new features. Keep an eye on the blog for the next in the series!

Name: David Parkin-Moore

Job title: Senior Product Manager Transmission Applications

Product: SABR

Spotlight Feature: Scuffing assessment in SABR-Gear

Q1: Tell us more about the new feature

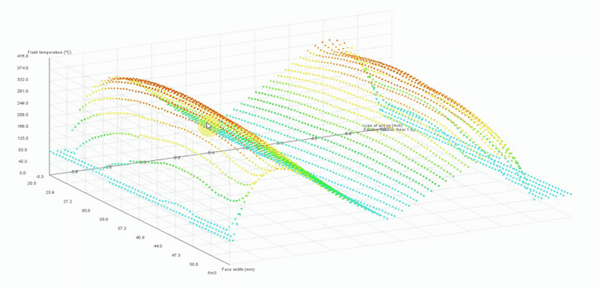

The tooth contact analysis has been enhanced to include a flash temperature calculation. This gives the user an accurate tool for assessing their macro and micro-geometry gear design against the risk of scuffing.

Q2: Why did Ricardo Software decide to include this functionality?

Scuffing as a failure mechanism is very detrimental. It can occur on a pair of gears within seconds of the beginning of a test and causes unacceptable NVH, wear and can lead to premature gearbox failure. The prevalence in transmissions of more traction fluids - used for wet clutches and lower viscosity oils to aid efficiency - has increased the occurrence of scuffing as a failure mechanism. Avoiding it at the early design stage, preferably at the macro-geometry level, will significantly reduce development time and effort and reduce warranty cost.

Q3: How will customers benefit from this new feature?

As it is part of the tooth contact analysis already carried out, there is no on-cost to the analysis time taken. It is a further check which the user can make to guide their macro and micro-geometry design.

Q4: What makes this new functionality so good?

The visualisation of the temperature distribution on the tooth surface and its incorporation within the tooth contact analysis. Hence both macro and micro-geometry are accounted for in one analysis.

Q5: Any plans for further development in the future?

This opens the door to the inclusion of micro-pitting analysis also within SABR-Gear.

We are hoping to look at generating parameter sweeps to allow multiple design cases to be run and results filtered.

Q6: How can our customers access the functionality and start enjoying the benefits?

This is included as part of SABR-Gear and is yet another additional feature added within the base package at no extra cost.

Customers can find out more about the updates available in SABR as part of the latest release by visiting the customer portal.