SABR

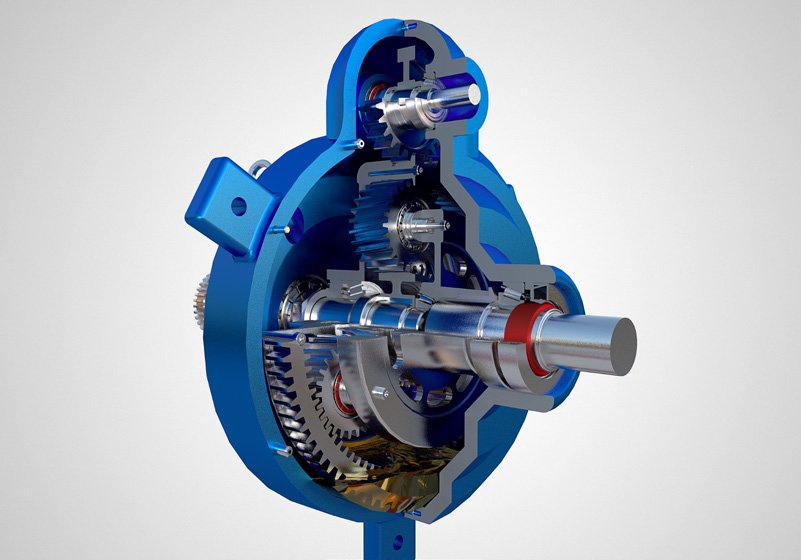

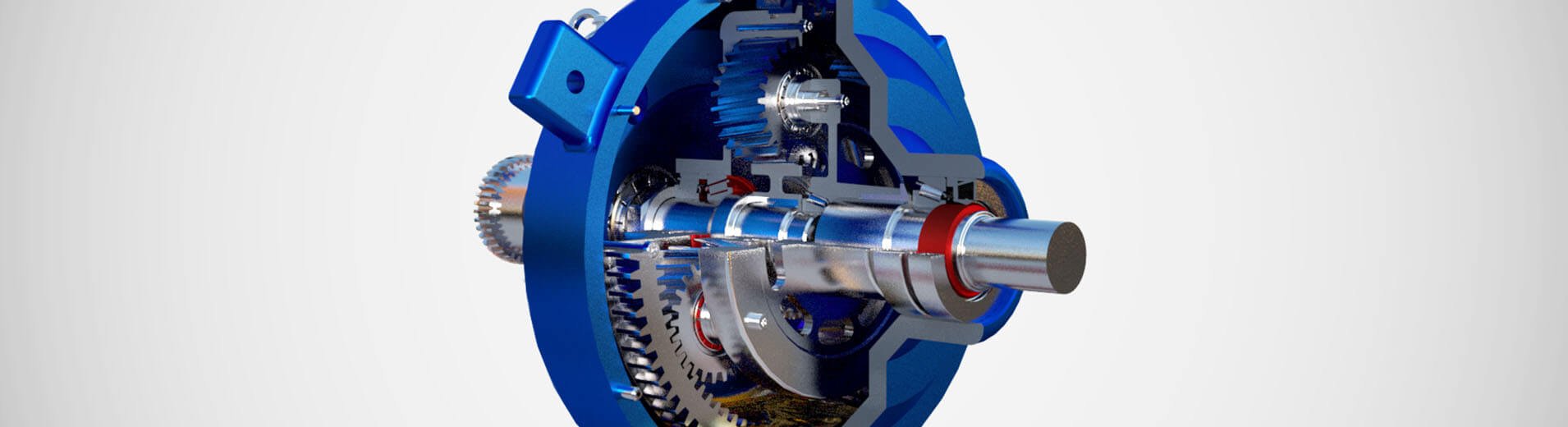

SABR is a proven shaft, gear and bearing concept design package.

SABR has been developed to integrate into the design process, reducing product development time by saving months of expensive durability testing. Using an intuitive graphical user interface, all or part of the transmission system can be modelled at a level of detail appropriate to the current design phase. Sensitivity studies to determine the effect of different geometric features, such as bearing types and gear positions can be performed quickly, delivering immediate results. SABR guides durability improvements and directs early NVH solutions whilst reducing gearbox losses, cost and weight, all instrumental in transmission efficiency.

Key features

- Simple intuitive GUI, with solver based on latest engineering standards

- Continually updated with real-world test and development data

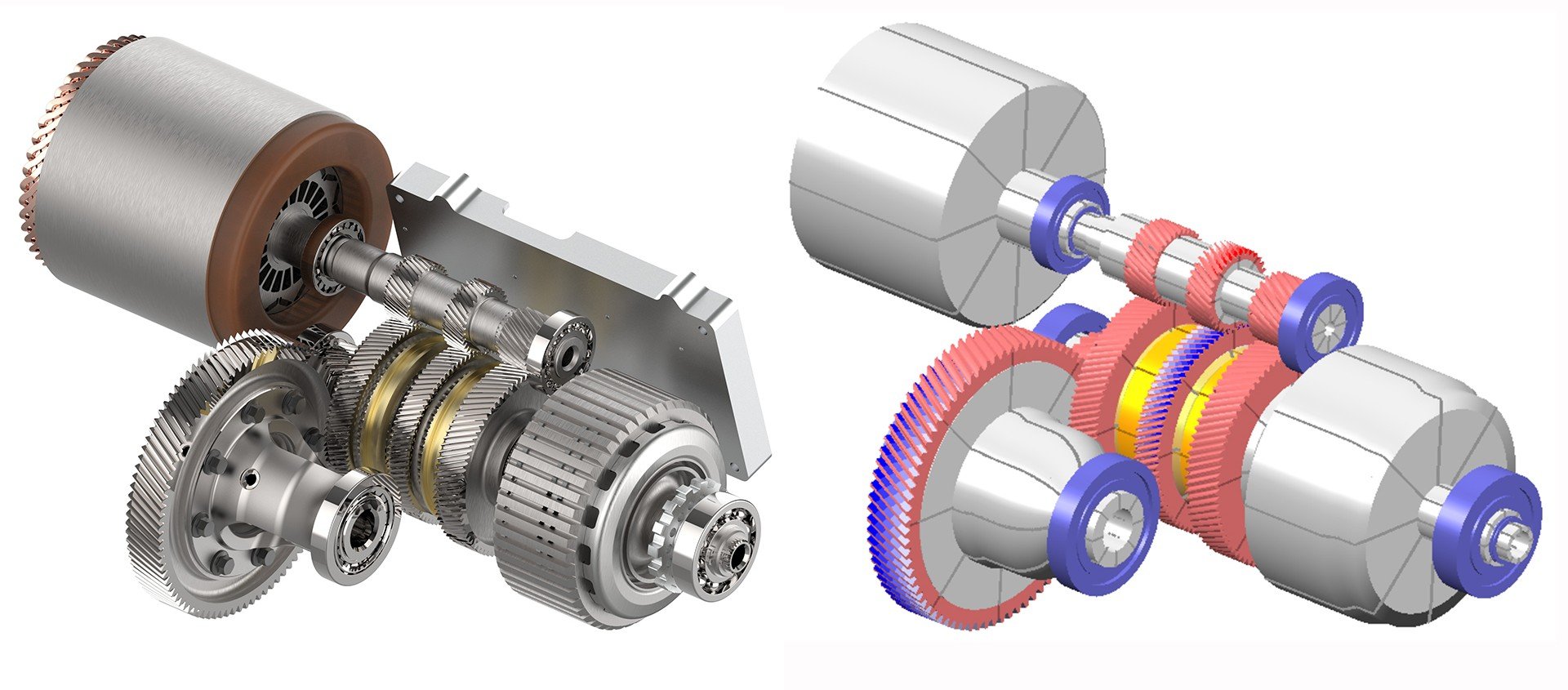

- Capability to model EDUs, manual, DCT, automatic, complex planetary and bevel applications

- Hybrid and split path gearboxes can easily be modelled with any number of power sources, absorbers or auxiliary drives

- Design for balanced input and output gear life to achieve target NVH criteria

- Tooth Contact Analysis (TCA) for micro-geometry design, transmission error, scuffing and micro-pitting analysis

- Bearing analysis with life calculation and stress plots accounting for loading, roller profiling and misalignment

- Casing stiffness matrices can be imported from major FE packages, or reduced using the Realis FEARCE solver

- Shaft design and fatigue analysis

- Transmission error export for NVH excitation of dynamic models

Our insights

Download resource

Electric vehicle NVH and efficiency using Motor-CAD and Ricardo Software

Conference

Reaching net-zero with Ricardo Software

Conference

Helping DS Performance win the Formula E Drivers and Teams Championships

Conference

Transmissions of the Future

White Paper