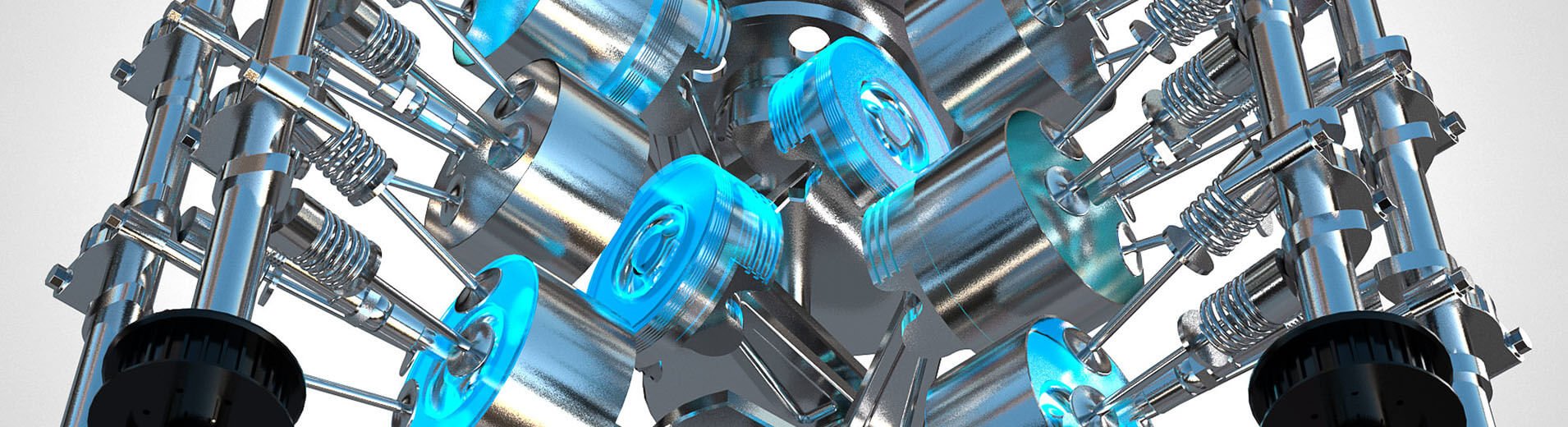

PISDYN

Reduce costs and development time through fast, accurate piston analysis

PISDYN is an advanced 3D simulation package used to predict piston and connecting rod assembly dynamics. A key benefit of PISDYN is that it enables users to quickly and efficiently optimise piston geometry helping to reduce the need for expensive and difficult testing.

How it works

PISDYN’s core technology is based around an advanced lubrication model that simulates the interfaces between the piston and liner, piston and piston pin, and wrist-pin and connecting rod. Through simulation, engineers can use a hierarchy of structural models to minimise scuffing, wear, friction loss and piston slap.

Key features

- ‘Advanced elastohydrodynamic (EHD) mass-conserving lubrication model for piston/liner interface’

- Hydrodynamic and boundary lubrication models

- Single-piece and articulated pistons

- Hierarchy of rigid, compliant and dynamic structural models

- Integrated FEARCE solver for finite element (FE) matrix reduction

Our insights

Download resource

From asperity to fuel economy – a digital friction study

Conference

Using Analytical Techniques to Understand the Impacts Intelligent Thermal Management has on Piston NVH

Technical Paper