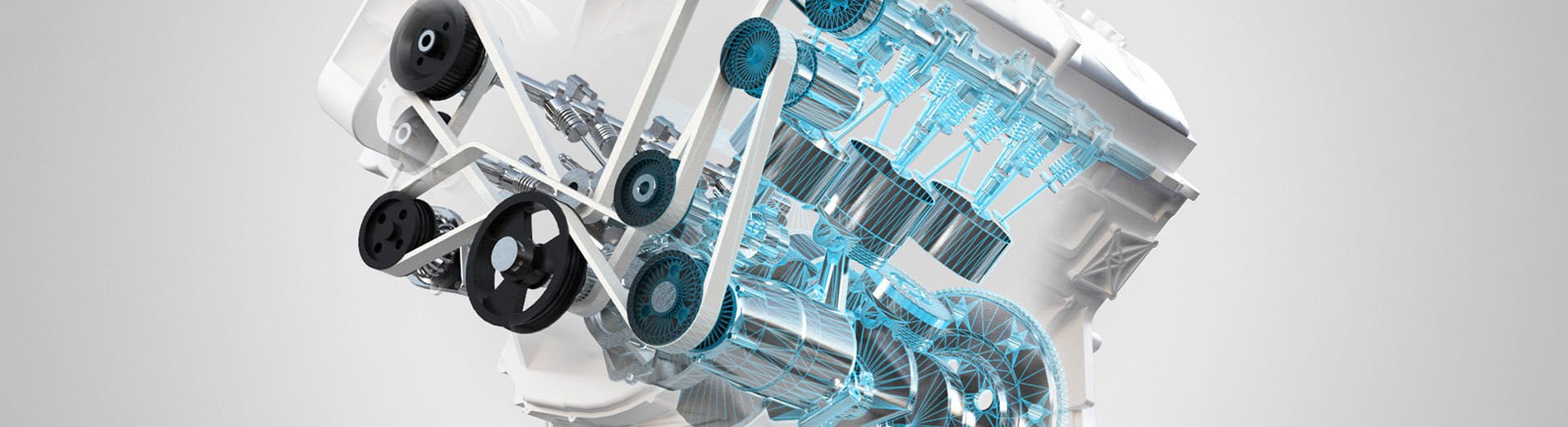

ENGDYN - crankshaft analysis

ENGDYN provides two methods of solution for predicting crankshaft durability, incorporating both a classical approach using simple beam theory as well as a more advanced finite element (FE) approach for more definitive studies. ENGDYN calculates both the quasi-static and vibratory loads on the crankshaft, and automatically sets up the necessary FE analysis. With its inbuilt fatigue module, ENGDYN can also provide both multi-axial and Goodman durability calculations for the key design areas on the crankshaft.

Specific crankshaft applications

- Crankshaft stress, fatigue and durability analysis

Key features

- Concept-level and fully 3D FEA solutions

- Automatic loading of FE models for solution

- Additional external loads

- Separation of static and vibration loading

- Effect of surface treatment on material strength

- Stress concentration and fatigue notch factors considered

- Uni-axial and multi-axial fatigue algorithms included